Biological Safety Cabinet Safety Considerations

A biosafety cabinet is considered one of the most important pieces of safety equipment in biological laboratories. BSC’s use laminar air flow and high efficiency particulate air (HEPA) filtration to contain aerosols generated during work with biological material.

Proper use of a BSC can provide a primary containment that:

- Protects the operator from infectious agents used inside the cabinet

- Protects the sample from contamination

- Provides protection for the laboratory environment from contaminants within the cabinet.

Definitions

Aerosol-producing Activities: May include, without limitation, opening containers with non-ambient pressures; intranasal inoculation of animals; harvesting infeted tissues/fluids, or embryonate eggs; transfer operations; necropsy of infected animals; changing animal cage bedding and operating aerosol-producing equipment.

Aerosol-producing Equipment: May include, without limitation, vortexers, blenders, sonicators, centrifuges, grinders, vigorous shakers and mixers. However, equipment (e.g. sealed rotors, buckets or centrifuge safety cups) that is designed to contain aerosols do not have to be operated in a BSC, provided that the containers (e.g. rotors or centrifuge safety cups) are opened only in a BSC.

National Sanitation Foundation (NSF): Regulatory agency responsible for the development of standards associated with the certificaion and testing of BSCs.

Primary Containment: The engineering control which prevents the release of potentially infectious material into the laboratory or outside the environment.

There are three types of BSCs (Class I, II, and III) that are used in laboratories. Open-fronted Class I and Class II BSCs are partial containment devices that provide a primary barrier offering significant levels of protection to laboratory personnel and to the environment when used in combination with good laboratory technique.

The Class I BSC is suitable for work involving low-to-moderate risk agents where there is a need for containment, but not for product protection. It provides protection to personnel and the environment from contaminants within the cabinet but does not protect the work within the cabinet from “dirty” room air. The air flow in a Class I BSC is similar to the flow inside a chemical fume hood, but it has a HEPA filter in the exhaust system to protect the environment. These BSC’s are mostly used to enclose lab equipment such as centrifuges or for procedures that may generate aerosols such as tissue homogenation.

The Class II BSC protects the material being manipulated inside the cabinet (e.g., cell cultures) from external contamination. It meets requirements to protect personnel, the environment, and the product. The two basic types of Class II BSCs are Type A and Type B. The major differences between the two types may be found in the percent of air that is exhausted or recirculated and the manner in which exhaust air is removed from the work area.

The gas-tight Class III BSC, or glove box, provides the highest attainable level of protection to personnel, the environment, and the product. It is the only unit that provides a total physical barrier between the product and personnel. It is used with high-risk biological agents and when absolute containment of highly infectious or hazardous material is required.

Laminar Flow Benches (LFBs): Also referred to as clean benches. They provide an aseptic environment for experimental work by passing HEPA filtered air across the work surface. It is important to note that horizontal laminar flow benches must not be utilized for work with biohazardous or chemically hazardous agents. These units provide product protection by ensuring the product is exposed only to HEPA-filtered air. They do not provide protection to personnel or the ambient environment.

BSC Maintenance

Proper operation and maintenance of a BSC requires knowledge of how the system operates, as well as training and experience in effective techniques for working within the cabinet volume without compromising its functions. Additional details concerning the design and use of BSCs are provided in the CDC’s Biosafety in Microbiological and Biomedical laboratories (BMBL) 6th edition.

Annual Certifications

- The certification ensures that the BSC is meeting its operating specifications and providing maximum protection. In addition, certifiers provide service and preventive maintenance for the BSC and can often forecast expensive requirements like HEPA filter replacements, allowing PIs to budget for the event.

- BSCs used as primary barriers must be certified annually. The initial certification is the responsibility of the PI. Please contact our office before scheduling your initial certification.

- The Office of Research Safety uses Technical Safety Services (TSS) for re-certifications, however the PI may choose another company for their initial certification.

- Once your initial certification is complete, please email a copy of your paperwork to our office at labsafety

gwu [dot] edu (labsafety[at]gwu[dot]edu )

gwu [dot] edu (labsafety[at]gwu[dot]edu ) - Our office is responsible for annual re-certifications.

- The recertification must be completed before the current certification expires. If the certification lapses, the BSC may not be used for BSL-2 or higher procedures until it is recertified.

- Please report any expired or soon-to-be expired certifications to ORS, so we can schedule your re-certification as soon as possible. The certificate will generally expire on the last day of the month in which the certification was performed, one year later (for example, a certificate issued on June 2, 2019 will expire on June 30, 2020).

- Prior to certification the user will be responsible for decontaminating the interior surfaces of the cabinet using an approved method and disinfectant specific to the agent.

- All copies of annual certification reports are maintained by the Office of Research Safety.

Routine Maintenance or Repairs

- All required maintenance and repairs will be performed by BSC certified technicians.

- The Office of Research Safety is responsible for re-certifications only. The PI is responsible for any service or repairs (ex. HEPA filter replacements).

- Any re-certifications required due to repairs will be the responsibility of the PI.

- Copies of maintenance or repair reports will be maintained by the PI and the Office of Research Safety.

Movement, Storage, Surplus or Disposal of BSCs

- Please notify the Office of Research Safety in advance when you plan to have a BSC moved, placed in storage, transferred to a new owner, discarded, removed from the University, or obtained from another institution or manufacturer.

- Prior to having the BSC moved the PI is responsible for ensuring proper decontamination of the BSC.

- BSCs must be professionally gas or vapor decontaminated by a certified technician before a unit is relocated, stored, or discarded based upon the agents which have been manipulated in the cabinet and the future usage of the BSC.

- Please contact Technical Safety Services (TSS) to schedule this decontamination.

- Once the BSC is decontaminated and moved, it must be re-certified prior to use.

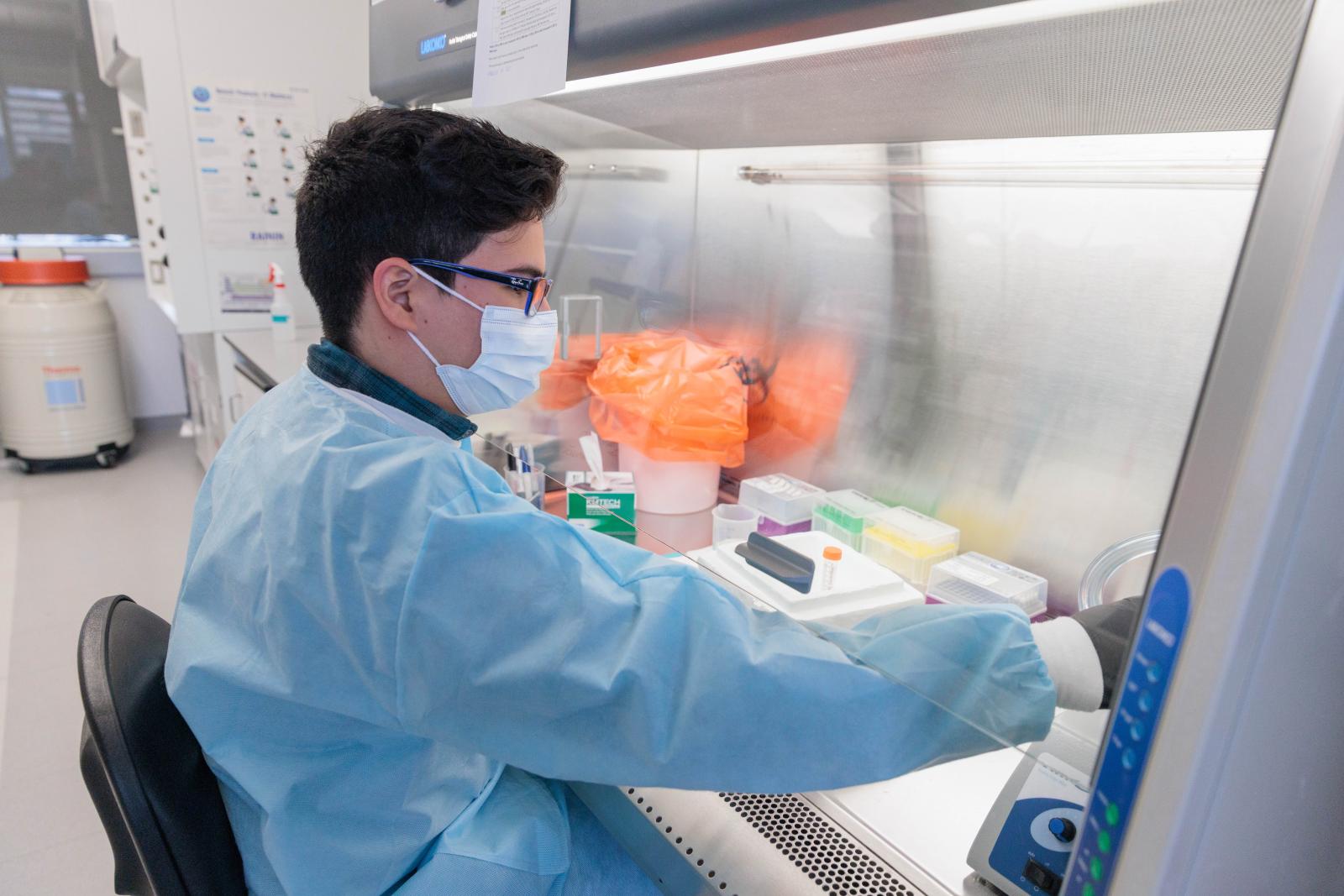

BSC Usage Guidelines

- Before initial use of the BSC, all users must complete the BSC training. Please contact our office to receive access to this training.

- Before working in the BSC, make sure the certification is current

- Do not use the BSC if any alarms are activated.

- Use of hazardous chemicals or open flame are STRICTLY prohibited in the BSC.

- Do not use the BSC as a storage area. Overcrowding the BSC with unnecessary items can affect airflow and containment.

- When working in the BSC proper PPE is required. At minimum a lab coat and gloves should be worn.

- Decontaminate BSC interior before and after each use with an approved disinfectant.

- Always open sash to correct working height.

- Always use proper aseptic technique.

- At least daily, or each time the cabinet is operated, the operator or user should observe the magnahelic gauge and note its relative position. Magnahelic gauges measure the pressure drop across the outlet HEPA filter and are important indicators of filter integrity and loading. The gauge will typically indicate the same measurement over a long period of time. A significant change in the reading over a short period of time may indicate clogging or a leaking filter. In such cases, the hood should not be used until the problem is identified and resolved. If the BSC located within a laboratory does not have a magnahelic gauge, users must understand the operation of the airflow monitor, controls, and alarm settings.

- For additional guidelines please use this BSC Checklist for daily BSC operation.

References

Baker Company, Introduction to Biological Safety Cabinets