Autoclave Safety

Autoclaves provide a physical method for disinfection and sterilization. They work with a combination of steam, pressure and time. Autoclaves operate at high temperature and pressure in order to kill microorganisms and spores.

Purpose

Sterilization refers to the complete killing of all living organisms, including spores.

Common sterilization techniques include the application of wet heat, dry heat, chemicals, and radiation. The type of material, the container, and quantity of items to be sterilized determines which method to use.

Despite built-in safeguards, an autoclave presents the possibility of serious injury to personnel from hot surfaces and from the release of steam. It is important, therefore, that laboratory personnel understand the proper operation, limitations, and safeguards for sterilization by autoclaving.

Associated Risks

Autoclaves are sterilizers using high pressure and high temperature steam. The potential safety risks for the operators are:

- Heat burns from hot materials and autoclave chamber walls and door

- Steam burns from residual steam coming out from autoclave and materials on completion of cycle

- Hot fluid scalds from boiling liquids and spillage in autoclave

- Hand and arm injuries when closing the autoclave door

- Body injury if there is an explosion

Autoclaves are used in laboratories to sterilize equipment, instruments, and infectious waste. All operators must receive training on the safe operation of the autoclave prior to using the equipment. Users should read and understand the owner’s manual from the particular model of autoclave that they are using.

Compatible/Incompatible Materials

| Autoclave Compatible | Autoclave Incompatible |

|

|

Safety Precautions

- Wear insulated thermal gloves when removing glassware from autoclaves. The OSHA fact sheet publication on Autoclaves and Sterilizers describes the DO’s and DON’Ts while working with autoclaves and Sterilizers.

- Assure that employees using the autoclave have been informed how to use autoclaves safely.

- All operators must receive training on the safe operation of the autoclave prior to using the equipment. Training may be delegated to a qualified individual, but it remains the responsibility of the supervisor to ensure their personnel are adequately trained.

- All glassware should be inspected prior to autoclaving. Older glassware can be less stable and may break during the process.

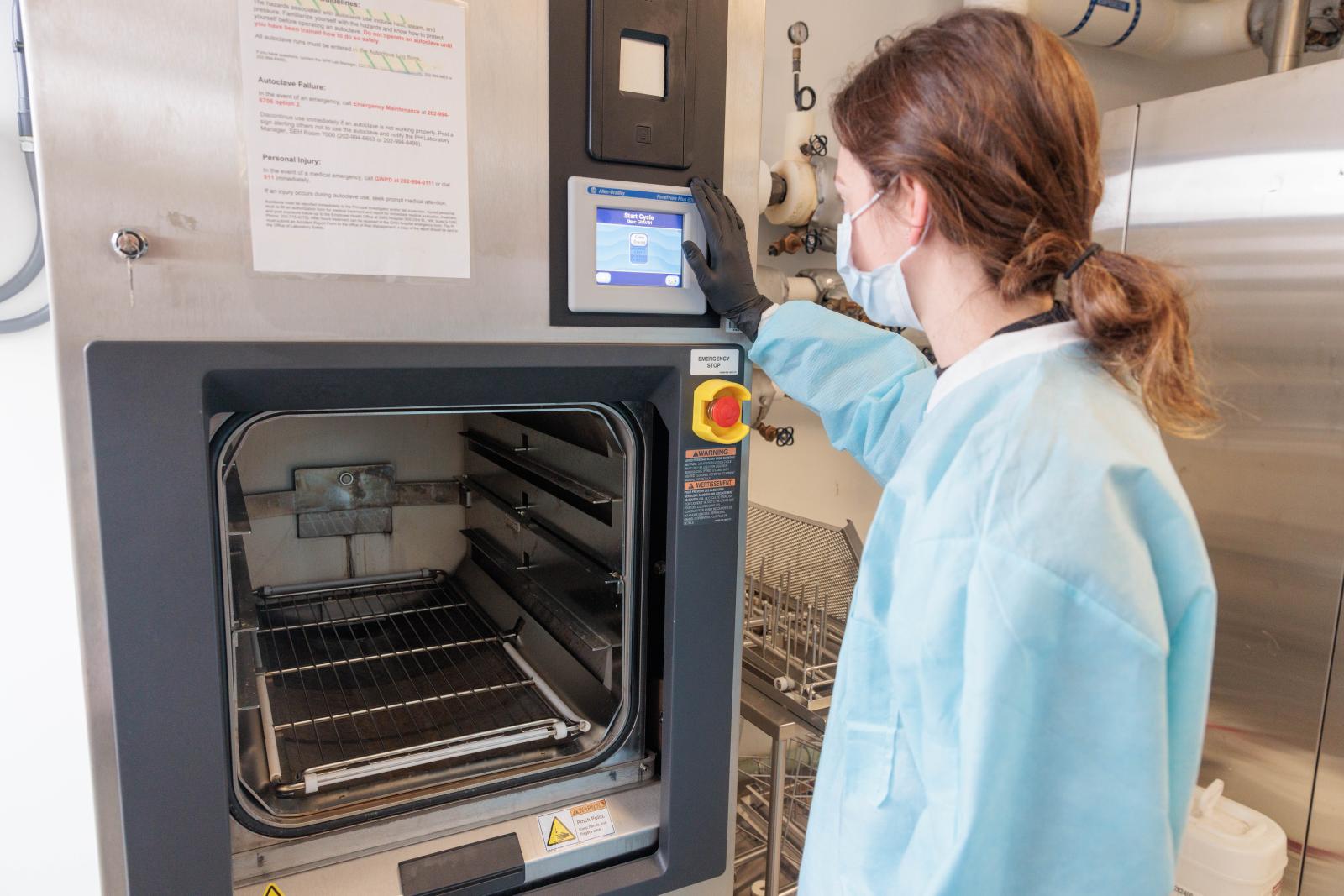

- Always wear suitable personal protective equipment. Closed toed shoes, lab coats and insulated gloves must be worn when handling autoclaved materials. When a splash hazard exists, face shields and aprons must be worn.

- When sterilizing liquids, use liquid cycle only and do not agitate containers of heated liquids, place containers in an autoclavable tray.

- Jarring containers can cause hot-bottle explosions. Allow materials to cool before transporting. Place containers on carts or trolleys lined with paper to avoid shattering of glass.

- Ensure all lids have loose, vented closures to prevent pressurization/vacuum.

- Sterilizers, racks, and materials will be very hot after processing. Stand back from the sterilizer when opening the door, and allow materials to cool before unloading.

- Immediately clean any spilled material or condensate from the floor to prevent slips or falls.

- Keep hands and arms out of the door opening when closing the sterilizer.

- Report any problems with the equipment, including unexpected noises, vibration, or smells to the person responsible for arraigning service.

- Place any sharps to be autoclaved in a designated sharps container.

- Do not attempt to open the door when a cycle is in process, or in the event of an alarm.

Never autoclave:

- Flammable, reactive, corrosive, toxic or radioactive materials

- Liquids in sealed containers

- Material contained in such a manner that it touches the interior surfaces of the autoclave

- Paraffin-embedded tissue sections

Autoclave Cycles

To be effective, the autoclave must reach and maintain a temperature of 121° C for at least 30 minutes by using saturated steam under at least 15 psi of pressure. Increased cycle time may be necessary depending upon the make-up and volume of the load.

The rate of exhaust will depend upon the nature of the load. Dry material can be treated in a fast exhaust cycle, while liquids and biological waste require slow exhaust to prevent boiling over of super-heated liquids.

| Cycle | Recommended for |

| Liquids Cycle |

|

| Solids or Dry Cycle |

|

| Wrapped Goods or Pre-vacuum Cycle |

|

Autoclave Procedure

Wear personal protective equipment:

- Lab coat

- Eye/face protection

- Closed-toe shoes

- Heat-resistant gloves to remove items, especially hot glassware

Packaging and Loading

Only designated individuals should be allowed to set and/or change parameters for the autoclaves.

Before using the autoclave, check inside for any items left by the previous user that could pose a hazard.

Clean the drain strainer before loading the autoclave.

Always place items in a secondary container.

Do not overload or package bags too tightly. Leave sufficient room for steam circulation. If necessary, place container on its side to maximize steam penetration and avoid entrapment of air.

Use only autoclavable bags to package waste.

Do not allow bags to touch the interior walls of the autoclave to avoid melting of plastic.

Ensure sufficient liquid is packed with contents of autoclave bags if dry.

Place soiled glassware and lab ware in secondary containers and autoclave them in the solids cycle. Do not fill containers more than 2/3 full with liquids. Loosen caps or use vented closures.

In case of clean glassware and wrapped instruments, lay them in a secondary container before autoclaving in wrapped goods cycle.

For secondary containment, use autoclave trays made out of polypropylene, polycarbonate or stainless steel. The trays should have a solid bottom and sides to contain the contents and catch spills.

Choose appropriate cycle for the material. Incorrect selection of cycle may damage the autoclave, cause liquid to boil over or bottles to break.

Start your cycle and fill out the autoclave user log. A completed cycle usually takes between 1 to 1.5 hours.

Check chamber/jacket pressure gauge for minimum pressure of 20 pounds per square inch (psi).

Close and lock door.

Check temperature for 250°F (121°C) every load.

Do not attempt to open the door while autoclave is operating.

Unloading

Ensure cycle has completed and both temperature and pressure have returned to a safe range.

Wear PPE described above, plus an apron and face shield if removing liquids. Stand back from the door as a precaution and carefully open door no more than 1 inch. This will release residual steam and allow pressure within liquids and containers to normalize.

Allow the autoclaved load to stand for 10 minutes in the chamber. This will allow steam to clear and trapped air to escape from hot liquids, reducing risk to operator.

Do not agitate containers of super-heated liquids or remove caps before unloading.

Place liquids in an area that indicates clearly that the items are “hot”.

Allow autoclaved materials to cool to room temperature before transporting. Never transport superheated materials.

Place cooled autoclaved biohazard bag into regulated medical waste box. Autoclaved infectious liquids may be disposed of into the sink.

Autoclave Log

The lab staff must maintain an autoclave log. The log should contain the following details:

- Date, time, and operator’s name

- Contact information: Laboratory, room number, phone number

- Type of material sterilized/cycle

- Temperature, pressure, and length of time the load is sterilized.

Autoclave Validation

Chemical Indicators

Tape Indicators

Tape indicators are adhesive-backed paper tape with heat sensitive, chemical indicator markings. Tape indicators change color or display diagonal stripes, the words “sterile” or “autoclaved” when exposed to temperatures of 121°C. Tape indicators are typically placed on the exterior of the waste load. If the temperature sensitive tape does not indicate that a temperature of at least 121°C was reached during the sterilization process, the load is not considered decontaminated. If tape indicators fail on two consecutive loads, notify your Department Safety Manager.

Tape indicators are not designed nor intended to prove that organisms have actually been killed. They indicate that a temperature of 121°C has been achieved within the autoclave. The Office of Research Safety (ORS) recommends that you DO NOT use autoclave tape as the only indicator of decontamination or sterilization.

Integrated Chemical Indicator Strips

Integrated chemical indicator strips provide a limited validation of temperature and time by displaying a color change after exposure to normal autoclave operating temperatures of 121ºC for several minutes. Chemical color change indicators can be placed within the waste load. If the chemical indicators fail on two consecutive loads, request service on the autoclave.

Biological Indicators

Biological indicator vials contain spores from B. stearothermophilus, a microorganism that is inactivated when exposed to 121°C saturated steam for a minimum of 20 minutes. Autoclaves used to treat biological waste must be evaluated with a biological indicator on a monthly basis.

Procedure

The indicators must be incubated for 24 hours at 60°C with a control that has been maintained at room temperature.

Results

If the autoclaved indicator exhibits growth, the validation has failed and must be repeated.

If the second validation indicator fails, request service on the autoclave. Autoclave should not be used until service has been conducted and the validation test passes.

Please send the validation tests results via email to the Office of Research Safety (ORS).

Broken Glass and Spills Cleanup

If broken glass is discovered, the autoclave should be left to cool completely before cleaning broken glass debris

The operator of the equipment is responsible for removing the broken glass and placing it in the designated broken glass container.

Spills may occur from boil over or breakage of containers. Do not attempt to operate the autoclave until the spill has been cleaned up.

If a spill occurs, prevent the spill from spreading and wait until both the autoclave and the material inside have cooled to room temperature. Do not attempt to clean a spill when it is hot. Clean affected area and dispose of waste appropriately.

The operator of the equipment is responsible for spill clean up.

Record the spill in the autoclave log book.

Click here for a PDF version of this content.